Your cart is currently empty!

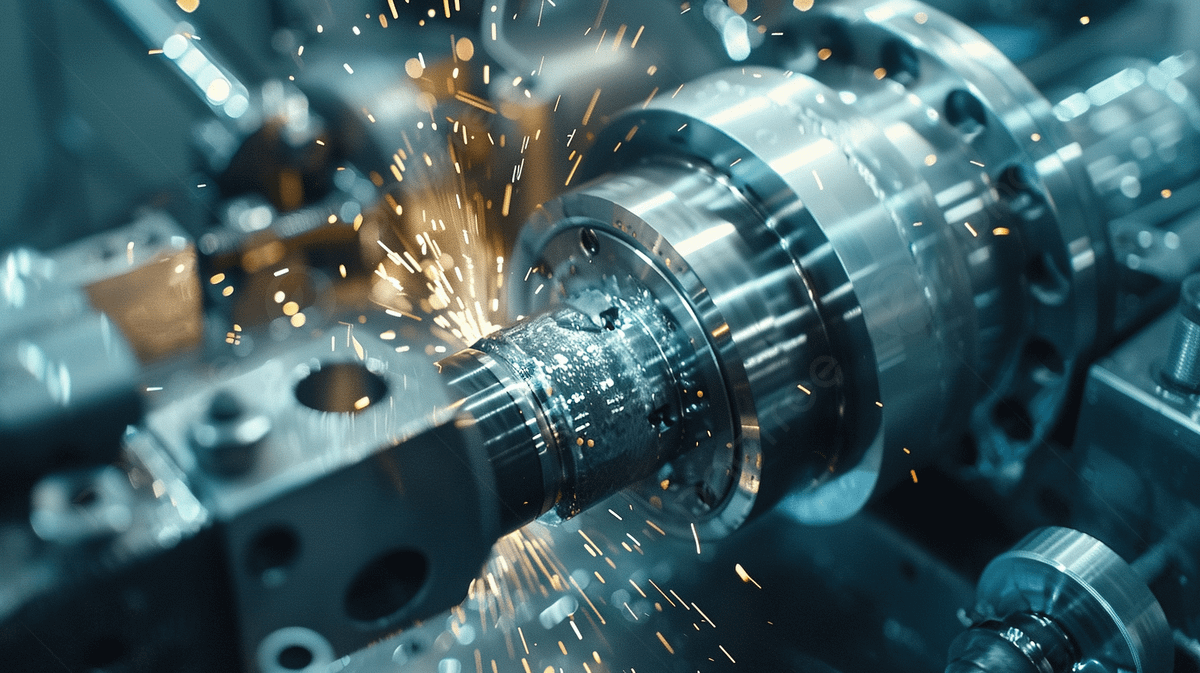

Aluminum Extrusion Processing

Aluminum Extrusion

AMG VietNam Company is one of the leading enterprises in the field of manufacturing products related to aluminum extrusion.

Extruding Equipment :

600 -> 4000 Ton EXTRUDER MACHINES

We can extrude with maximum dimensions up to:

480×450 mm (WxH)

With us we are always committed to:

Product quality: Specializing in providing extruded aluminum products with high precision, beautiful surface finish and good durability.

Professional team: We own experienced, highly skilled partner companies in the aluminum extrusion manufacturing industry.

We do anything with Aluminum Extrusion products !

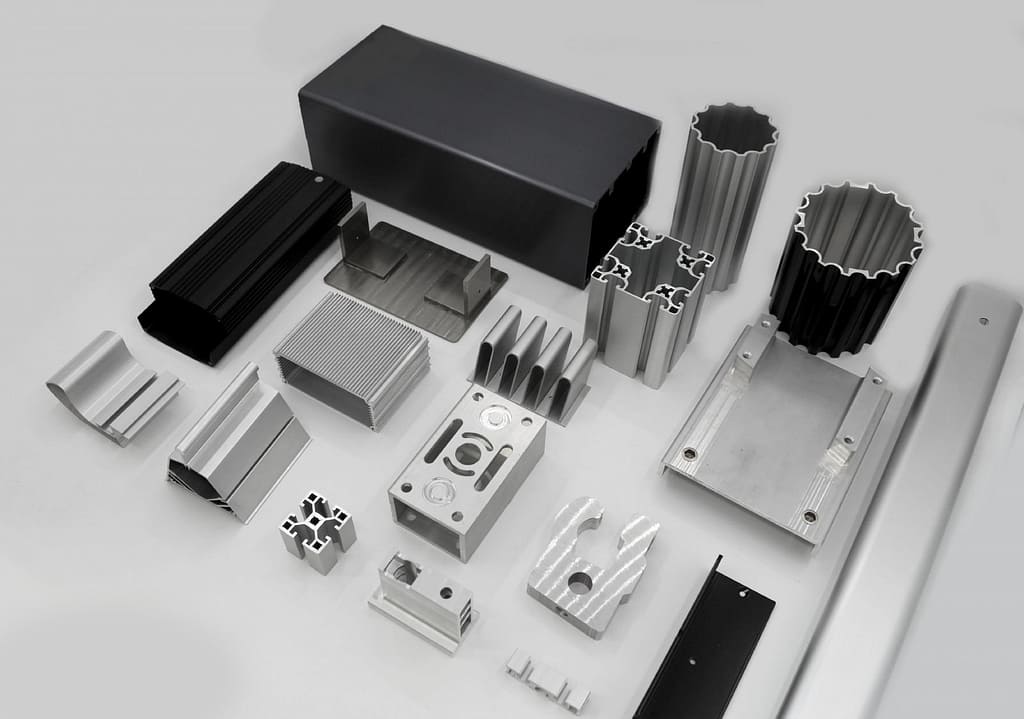

WHY ALUMINUM EXTRUSION?

Design and produce nearly any shape—in a timely manner— through a low-cost process.

By offering designers a near net shape of their choice, aluminum extrusions are unrivaled among structural materials for design selection. The only limit is your imagination.

For a hollow die shape, the can flow through the opening between the part of the die that forms the outside diameter and the inside “mandrel” supported by two horizontal supports.

The into two tube halves and “welds” back together due to the pressure needed to make it flow through the annular opening into a tube shape

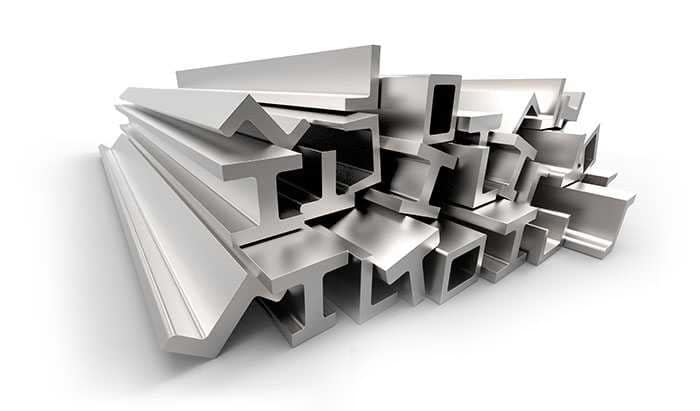

ALUMINUM & SUSTAINABILITY

Lightweight, strong, durable, corrosion-resistant, versatile, low-maintenance, flexible, fast.

Aluminum extrusions help product designers, engineers, and architects get to destinations that steel can’t reach. As one of the most recycled industrial materials, it also makes a substantial contribution to sustainability efforts.

Aluminum Advantages in Sustainability

Aerospace

Aircraft Components: Aluminum’s high strength-to-weight ratio makes it suitable for structural parts, including wing components, fuselage frames, and landing gear.

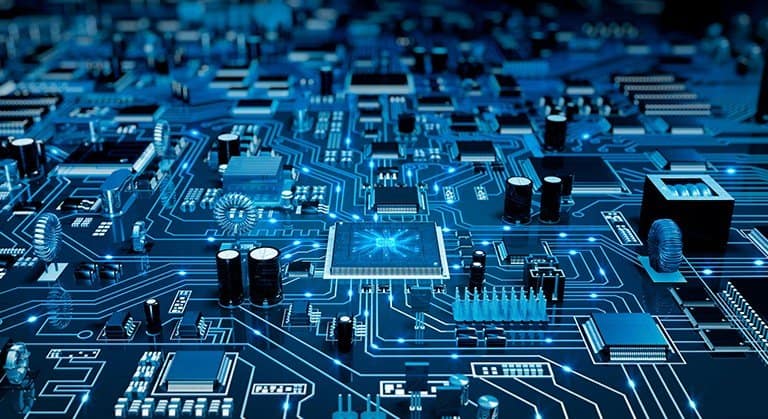

Electronics and Electrical

Heat Sinks: Aluminum extrusions are used to dissipate heat from electronic components, improving performance and longevity.

Enclosures and Racks: Used in the housing of electronic equipment and server racks due to their thermal and mechanical properties.

Transportation and Rail

Railway Systems: Extrusions are used in rail carriages, track components, and other infrastructure.

Buses and Trains: They contribute to lightweight, fuel-efficient designs.

Industrial Applications

Machine Frames: Custom extrusions are used for building machine frames and supports.

Workstations: Modular workstations and assembly lines often incorporate aluminum extrusions for flexibility and strength.

Automotive Industry

Vehicle Frames and Chassis: Lightweight aluminum extrusions contribute to fuel efficiency and performance in vehicles.

Interior Components: Used in dashboards, trim, and other interior elements for a sleek, modern look.

Construction and Architecture

Structural Components: Aluminum extrusions are used for window frames, curtain walls, doors, and roofing systems. Their durability and resistance to corrosion make them ideal for both residential and commercial buildings.

Facades and Cladding: They provide aesthetic appeal and functional benefits in building facades and cladding systems.