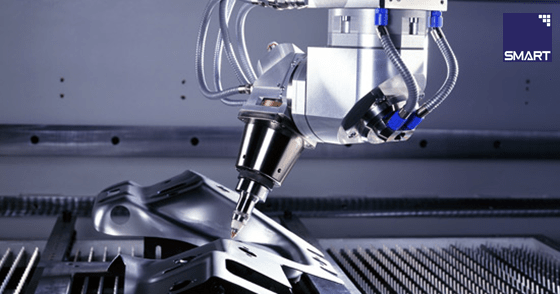

A computer numerical control (CNC) milling machine is a mill that uses computer code to understand where to make cuts.

Like all milling machines, a CNC mill produces a final piece by carving away from a block of material versus adding layers of material to a blank slate. However, unlike manual milling, CNC mills do not have to be operated by hand. You simply need the right computer software and a library of programs to instruct your machine on how to create the desired product.

CNC milling is just one type of CNC machining process your business could consider integrating to make your production more accurate and efficient.

We’ll cover the advantages of CNC milling, which industries can benefit from using a CNC mill and how a CNC mill works.

Why Should You Use a CNC Milling Machine?

CNC milling has many advantages over manual milling, and this automated process can serve various industries — particularly sectors in which accuracy and consistency are paramount.

Advantages of CNC Milling

Because CNC mills operate based on computer programs rather than with manual workers, the process creates several benefits to boost your business’s bottom line, including:

- Greater precision: With computer programs running the cuts, CNC mills allow you to reach a higher level of precision than you could with a manual machine. Because these machines don’t rely on human operators, they leave less room for human error.

- More consistency: Another advantage of not having a human operator and minimizing human error is that CNC mills can produce more consistent products. If you need pieces that align precisely, take advantage of CNC milling’s automated uniformity.

- Less waste: Fewer errors mean CNC mills produce less waste. CNC machines can achieve higher efficiency with their cuts than manual machines.

- Faster production: Because they’re more efficient and don’t require a human operator, CNC machines can also complete a product much more quickly than manual mills.

- Less labor-intensive: Save on labor costs by outsourcing to a company that offers CNC milling. Doing so will also free up your current employees to work on other critical tasks because they no longer have to spend time operating a manual machine.

- Simplified complexity: If your piece requires many different cuts, tools or materials, many large CNC machines can more seamlessly integrate these changes, further contributing to a quicker, more efficient production process.

While CNC milling machines can be a costly investment, outsourcing your production to a company like Astro Machine Works allows you to take advantage of each of these benefits without paying the upfront cost of owning a CNC mill yourself.

Additionally, our operators have experience working with the software, which means you can trust us to produce high-quality products. By relying on our expertise, you benefit from the efficiency of CNC milling without dedicating the time and resources to learn the software yourself.

Applications

CNC milling machinery is widely used across various industries for producing high-precision parts and components. Some common applications of CNC milling machinery include:

- 1. Aerospace Industry: CNC milling machines are used to manufacture aircraft components such as engine parts, brackets, panels, and more with tight tolerances and complex geometries.

- 2. Automotive Industry: CNC milling is utilized for creating automotive parts like gears, shafts, pistons, and other critical components that require accuracy and consistency.

- 3. Medical Industry: In the medical field, CNC milling machines are employed to produce custom implants, surgical instruments, prosthetics, and other medical devices with precise specifications.

- 4. Electronics Industry: CNC milling is used for manufacturing printed circuit boards (PCBs), electronic enclosures, connectors, and other intricate electronic components.

- 5. Prototyping and Rapid Manufacturing: CNC milling is ideal for rapid prototyping of new product designs as it allows quick iterations and modifications before mass production.

- 6. Mold Making: CNC milling machines are crucial in mold making processes for creating molds used in plastic injection molding or die-casting operations.

- 7. Tooling Industry: CNC milling is essential for producing cutting tools, jigs, fixtures, and other tooling equipment required in manufacturing processes.

- 8. Architectural Applications: CNC milling can be used to create architectural models, decorative elements, signage, and customized features with intricate details. Overall, the versatility of CNC milling machinery makes it a valuable asset in a wide range of industries where precision machining is essential.

If you have a requirement for machining details, please contact us for CNC milling and CNC turning in small and medium quantities. Contact AMG VIETNAM INDUSTRIAL CO., LTD now. AMG is a mechanical processing manufacturer in Vietnam. The best and most affordable miling machining manufacturer in Vietnam

Leave a Reply