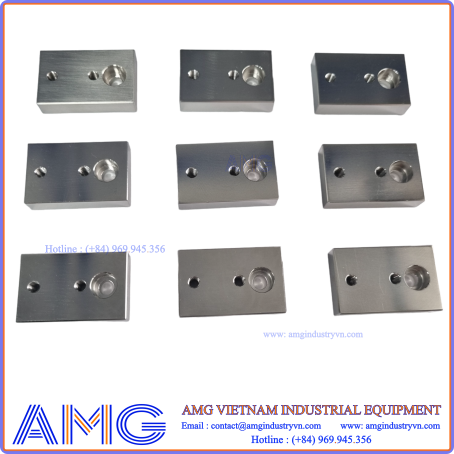

AMG Vietnam is a leading name in the field of professional manufacturing, especially in the field of CNC Milling Machines. With a strong focus on precision and quality, we have established ourselves as a trusted partner to customers worldwide.

At AMG Vietnam, we understand the importance of delivering products that meet the highest industry standards. With state-of-the-art facilities and a team of highly skilled technicians, we are able to provide precision machining solutions for a wide range of industries.

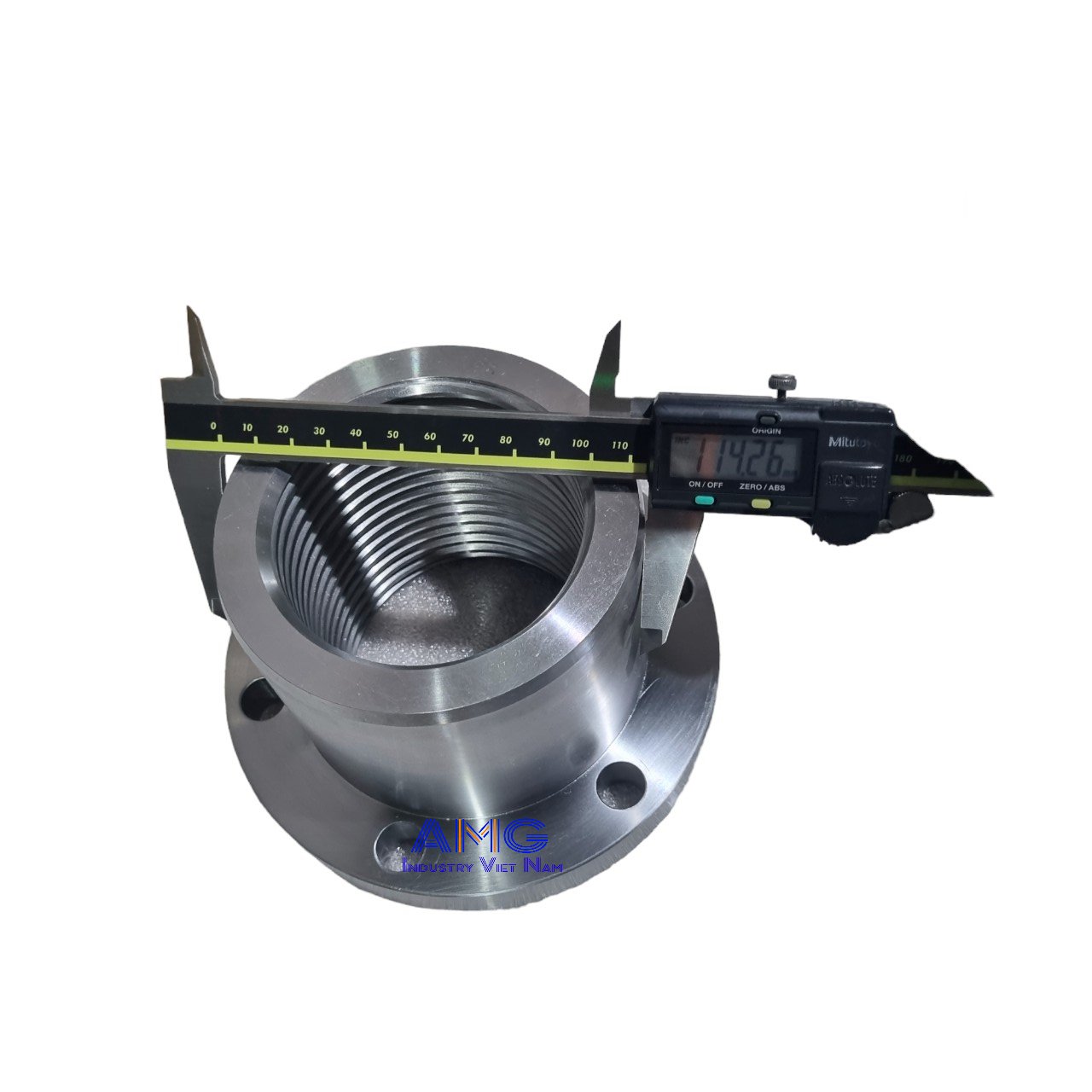

Workpiece Size And Tolerances

Milling envelope: 3000 x 1500 x 450 mm (118 x 60 x 18 in)

Tolerances: We specify standard dimensional tolerances of ±0.005” for CNC machined parts.

We can make tighter tolerances depending on the product’s shape and material.We always comply with drawing tolerances and customer requirements

We have a team of production technical experts , who can advise customers to ensure the characteristics of Spare Parts help reduce costs and satisfy even the most demanding customers.

With the motto: win~win

Total number of milling : 15 units

- International Quality

- Competitive Price

- Time Delivery

Materials

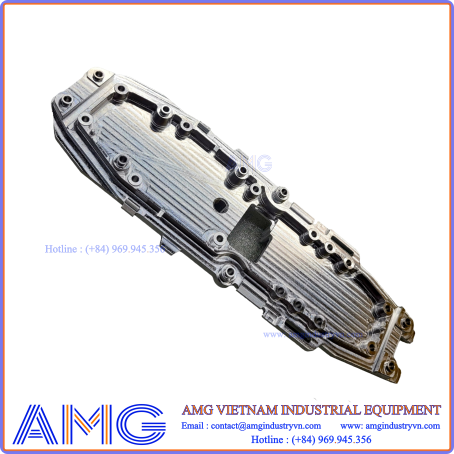

We buy and import materials under ASTM, JIS, DIN, GB standards. All common engineering-grade metals and plastics are available: Metals: Aluminum, Brass, Copper, Stainless Steel, Steel Alloy, Inconel, Titanium. Plastics: ABS, PC, PMMA, PEEK, PTFE (Teflon), POM (Delrin), PA (Nylon). If required, we can produce material certificates and inspection reports. We just ask that this information is requested upfront as it becomes difficult to get material certifications afterward. We also maintain solid partnership with selected local suppliers for preformed materials, including: Aluminum die casting (we design and make the tools) Aluminum extrusion .Stainless steel or aluminum investment casting (lost-wax casting) Gravity casting, sand casting

SURFACE FINISH OPTIONS FOR PARTS

Turned parts often have very fine surface finishes such as cylindrical tools.

Areas will often be much cleaner when using a lathe for milling, so consider this when choosing your machining method

method for parts that qualify for either method. The fields are cut with the direct tool, which is limited as possible by facades and fields.

You can find traces. If desired, metallic parts can be lightly bead blasted to leave a hard, metallic finish.

Steel and stainless steel can also be tempered (reduced) by light blasting to remove metal fragments, and

sharp or steep areas.

SURFACE FINISH

- Anodizing (Anodizing hard , White ,Silver ,Red ,Yellow ,…)

- Heat treatment ;Inductioning ;Annealing ;Quenching ;Tempering; Quenching& Tempering

- Gas nitriding;Carburizing

- Galvanized; Nickel plating ; Electroless Nickel plating ;Chrome plating ; Hard Chrome plating….

Product

CuSn12/C8600/C3600

Sus304/Sus316/Sus440C/Sus630

A5052/A6061/A6082/A7075

Steel : SS400/S45C/SUS420/SCM440

Acetal/Teflon/PA6/Acrylic